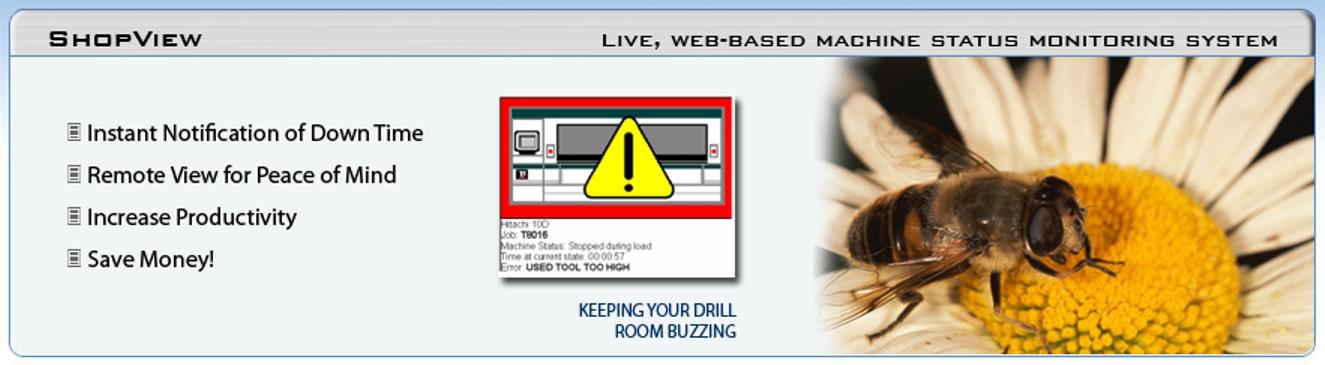

At FASTechnologies, drill room efficiency is our business. Our products eliminate scrap before it happens. Now you can monitor and increase your drill room performance, detecting problems before time is lost and money wasted.

This central “heads up display” is the command center for your entire drill room. The web-based status view instantly tells you and your drill operators where the trouble is… and where it isn’t. One glance at the display, and your operators know right where to go to keep your drilling and routing machines running.

With your operators freed from having to watch running machines, they can spend their time more productively. They can prepare the coming loads, load tool cassettes, and perform all of the other “care and feeding” tasks of drilling and routing, without fear that they’ll overlook that stopped machine on the far side of the drill room. That save time and money, especially in times when fewer operators must run more machines.

In our studies, the ShopView system reduces your machine stop time by a minimum of fifteen minutes a day. It also frees up over an hour a day of each machine operator’s time, so they can do other work. In a three-shift operation, the daily cost savings is worth about $40 per machine, and the three hours of added operator labor availability is worth about $60.

Even in an eight-machine shop, the cost savings of $380 per day will pay for the complete system in under four months. So this system is an investment which pays about a 300% return in the first year! That’s why companies invest in FASTechnologies products like the ShopView system, especially in a difficult market.